Bags

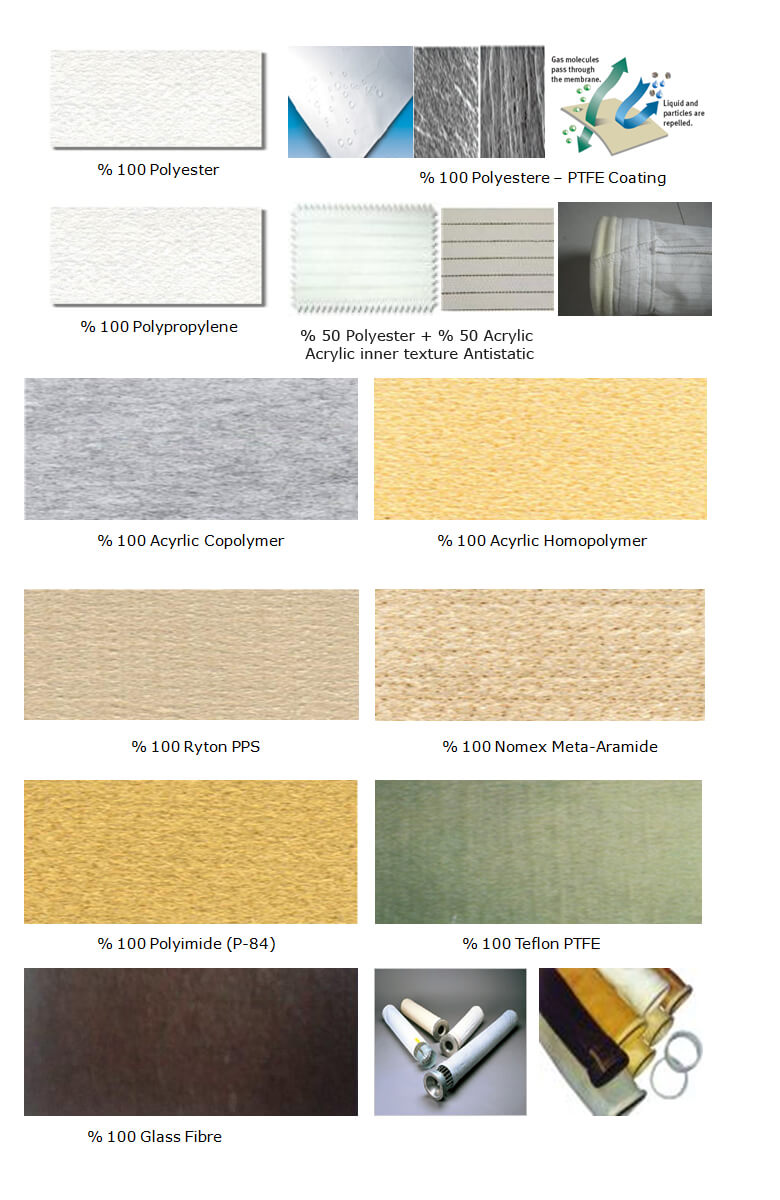

Needle Felt filter bags used in dust and liquid filtration are produced depending on operation conditions using felt fabrics made of %100 Polyester, %100 Polypropylene, %100 Homopolymere Acrylic (Dolanit), %100 Copolymer Acrylic, %100 Ryton (Polyphenylsulfide),%100 Meta-Aramid (Nomex),%100 Polyimide (P-84),%100 Teflon (PTFE), %100 Fibre glass and their quality is in accordance with European Norms

Inner textures of the fabrics differ according to the qualification of the material. In the polyester filter bags polyester staple based inner textures are used for the operations required normal resistance and polyester multiflament based inner texture is used for the operations required high resistance.The inner texture of the other fabrics like Polypropylene, Dolanit, Copolymer Acrylic is Acrylic. Also the inner texture of Ryton, Polyimide (P-84), Teflon (PTFE) is teflon. The inner texture of %100 Nomex (Meta-Aramid) is manufactured from their own material.Because fiberglass products have fragile feature,they are produced as woven instead of non-woven and for this reason they have not inner texture. All our products are having the treatments of singeing and calendering .If required teflon hydrophob impregnation is applied to give the feature of water and oil repellent.The dust holding surface can be covered with e-PTFE membrane to ease the shaking and delay decreasing the air permeability by preventing dust from penetrating through the felt pores. .

The sewing thread made of the same material with the inner texture of the bag fabric is used in the operations of sewing filter bags.The longitudinally sewing of the bags is done with special sewing technique of chain type by using high strength sewing thread with doubled three rows and the same sewing method is applied for sewing the base cover part. Otherwise the bags working in the system selected properly for the system might be torn because of unwrapping in the base cover or longitudinally.Therefore this causes the bags used in the system to have short life.

CHEMICAL RESISTANCE TECHNICAL SPECIFICATIONS OF NEEDLE FELT FILTER MATERIALS |

|---|

| CONTENT (ISO 1043-1) | CODE NO FILTERELEMENT FE | WEIGHT (TS EN 29073-1) | AIR PERMEABILITY (ISO 1043-1) lt /dm²/hour. Dp:200 Pa. | RESISTANCE (ISO 5081) Longitudinal - Latitudinal | THIKNESS (DIN 53517) | SURFACE TREATMENT | TEMPERATURE |

|---|---|---|---|---|---|---|---|

| Polyester (Stapel Inner texture) | P.E-360 | 360 gr / m² ± % 5 | 20.000 | 0-80 kgf / 5 cm | 1,5 mm | NA | 150°C |

| Polyester (Stapel Inner texture) | P.E-380 | 380 gr / m² ± % 5 | 19.000 | 40-80 kgf / 5 cm | 1,5 mm | NA | 150°C |

| Polyester (Stapel Inner texture) | P.E-400 | 400 gr / m² ± % 5 | 10.800 - 14.500 | 50-100 kgf / 5 cm | 1,8 mm | C+S | 150°C |

| Polyester (Stapel Inner texture) | P.E-400 | 400 gr / m² ± % 5 | 10.800 - 14.500 | 50-100 kgf / 5 cm | 1,8 mm | C+S+T | 150°C |

| Polyester (Stapel Inner texture) | P.E-525 | 525 gr / m² ± % 5 | 11.000 - 14.000 | 90-150 kgf / 5 cm | 2,0 mm | C+S | 150°C |

| Polyester (Stapel Inner texture) | P.E-525 | 525 gr / m² ± % 5 | 11.000 - 14.000 | 90-150 kgf / 5 cm | 2,0 mm | C+S+T | 150°C |

| Multiflament (Inner texture) | P.E.M-525 | 525 gr / m² ± % 5 | 11.000 - 14.000 | 150-190 kgf / 5 cm | 2,0 mm | C+S | 150°C |

| Polyester( Multiflament inner texture) | P.E.M-525 | 525 gr / m² ± % 5 | 11.000 - 14.000 | 150-190 kgf / 5 cm | 2,0 mm | C+S+T | 150°C |

| Polyester(Stapel Inner texture) | P.E-550 | 550 gr / m² ± % 5 | 9.000 - 11.000 | 150-190 kgf / 5 cm | 2,2 mm | C+S | 150°C |

| Polyester (Stapel Inner texture) | P.E-550 | 550 gr / m² ± % 5 | 9.000 - 11.000 | 150-190 kgf / 5 cm | 2,2 mm | C+G+T | 150°C |

| Polyester(Multiflament Inner texture) | P.E.M-550 | 550 gr / m² ± % 5 | 9.000 - 11.000 | 150-190 kgf / 5 cm | 2,2 mm | C+S | 150°C |

| PPolyester(Multiflament inner texture) | P.E.M-550 | 550 gr / m² ± % 5 | 9.000 - 11.000 | 150-190 kgf / 5 cm | 2,2 mm | C+S+T | 150°C |

| Polyester(Multiflament Inner texture) | P.E.M-600 | 600 gr / m² ± % 5 | 6.000 - 9.000 | 150-190 kgf / 5 cm | 2,4 mm | C+S | 150°C |

| Polyester(Multiflament inner texture) | P.E.M-600 | 600 gr / m² ± % 5 | 6.000 - 9.000 | 150-190 kgf / 5 cm | 2,4 mm | C+S+T | 150°C |

| Polyester+e-PTFE | P.E.e-PTFE-550 | 550 gr / m² ± % 5 | 4.000 | 110-140 kgf / 5 cm | 2,5 mm | C+S | 150°C |

| Polypropylene | P.P-525 | 525 gr / m² ± % 5 | 9.000 | 110-140 kgf / 5 cm | 2,0 mm | C+S | 90°C |

| Polypropylene | P.P-525 | 525 gr / m² ± % 5 | 9.000 | 110-140 kgf / 5 cm | 2,0 mm | C+S+T | 90°C |

| (Polyester+Acrylic)Antistatic | P.A-525 | 525 gr / m² ± % 5 | 11.000 - 14.000 | 110-140 kgf / 5 cm | 2,0 mm | C+S | 130°C |

| (Polyester+Acrylic)Antistatic | P.A-525 | 525 gr / m² ± % 5 | 11.000 - 14.000 | 110-140 kgf / 5 cm | 2,0 mm | C+S+T | 130°C |

| (Polyester+Acrylic)Antistatic | e-PTFE | P.A-550 550 gr / m² ± % 5 | 4.000 | 110-140 kgf / 5 cm | 2,5 mm | C+S+T | 150°C |

| Acrylic Copolymer | A.C-525 | 525 gr / m² ± % 5 | 11.000 - 14.000 | 110-140 kgf / 5 cm | 2,0 mm | C+S+T | 130°C |

| Acrylic Copolymer | A.C-525 | 525 gr / m² ± % 5 | 11.000 - 14.000 | 110-140 kgf / 5 cm | 2,0 mm | C+S | 130°C |

| Acrylic Homopolymer | A.H-525 | 525 gr / m² ± % 5 | 9.000 - 11.000 | 110-140 kgf / 5 cm | 2,0 mm | C+S | 130°C |

| Acrylic Homopolymer | A.H-525 | 525 gr / m² ± % 5 | 9.000 - 11.000 | 110-140 kgf / 5 cm | 2,0 mm | C+S+T | 140°C |

| Ryton P.P.S.Polyphenylsulfide | Ryton-525 | Ryton-525 | 9.000 - 11.000 | 70-120 kgf / 5 cm | 2,0 mm | C+S | 180°C |

| Ryton P.P.S.Polyphenylsulfide | Ryton-525 | 525 gr / m² ± % 5 | 9.000 - 11.000 | 70-120 kgf / 5 cm | 2,0 mm | C+S+T | 180°C |

| Nomex Meta - Aramide | Nomex-400 | 400 gr / m² ± % 5 | 11.000 - 14.000 | 110-140 kgf / 5 cm | 1,8 mm | C+S | 200°C |

| Nomex Meta - Aramide | Nomex-400 | 400 gr / m² ± % 5 | 11.000 - 14.000 | 110-140 kgf / 5 cm | 1,8 mm | C+G+T | 200°C |

| Nomex Meta - Aramide | Nomex-400 | 400 gr / m² ± % 5 | 11.000 - 14.000 | 130-170 kgf / 5 cm | 1,8 mm | C+S | 200°C |

| Nomex Meta - Aramide | Nomex-400 | 400 gr / m² ± % 5 | 11.000 - 14.000 | 130-170 kgf / 5 cm | 1,8 mm | C+S+T | 200°C |

| Polyimide P-84 | Polyimide-525 | 525 gr / m² ± % 5 | 9.000 - 11.000 | 130-170 kgf / 5 cm | 2,0 mm | C+S | 260°C |

| Polyimide P-84 | Polyimide-525 | 525 gr / m² ± % 5 | 9.000 - 11.000 | 130-170 kgf / 5 cm | 2,0 mm | C+S+T | 260°C |

| Teflon PTFE | Teflon-750 | 750 gr / m² ± % 5 | 9.000 | 150-200 kgf / 5 cm | 2,0 mm | C+S | 270°C |

| Glass Fibre | Glass Fibre-770 | 770 gr / m² ± % 5 | 3.000 | 150-200 kgf / 5 cm | 1,7 mm | C+S+e-PTFE | 290°C |

- Data placed in the column of air permeability is given as lt/dm²/h under the pressure difference of Dp:200 Pa

- All data placed in the column of Resistance is given in the order of Longitudinal-Latitudinal

- In the column of Surface Treatment , C= Calendering, T= Teflon Hydrophob Impregnating(oil and water repelling) S= Singeing e-PTFE = PTFE Membrane-covered

- All data given in the board is compatible with ISO and TSE standards . (ISO 1043-1), (TS EN 29073-1), (ISO 1043-1), (ISO 5081), (DIN 53517)

CHEMICAL RESISTANCE TECHNICAL SPECIFICATIONS OF NEEDLE FELT FILTER MATERIALS |

|---|

| MATERIAL | PE | PE+ePTFE | PP | PA | AC | AH | PPS | NX | P-84 | PTFE | GF |

|---|---|---|---|---|---|---|---|---|---|---|---|

| ACİD | 2 | 2 | 4 | 3 | 2 | 2 | 4 | 2 | 3 | 3 | 3 |

| Alkali | 1 | 1 | 4 | 1 | 2 | 2 | 4 | 2 | 2 | 3 | 1 |

| Hydrolysis | 1 | 1 | 4 | 1 | 4 | 4 | 4 | 2 | 1 | 3 | 3 |

| Oxidation | 4 | 4 | 1 | 4 | 3 | 3 | 2 | 3 | 3 | 4 | 4 |

| Solvent | 4 | 4 | 3 | 4 | 3 | 3 | 2 | 3 | 3 | 4 | 4 |

1) Weak 2) Medium 3) Good 4) Very Good